Introduction Of Melamine Plate

Melamine plate that is melamine plate, also known as double decorative panels, some people call it a molding board. Its base material is plywood, mdf or particleboard and so on, by base material and surface agglutinate become, because be through fireproof, antiwear, waterproof soak processing. Melamine board, initially used to do computer desk and other office furniture, mostly monochrome board, with the popularity of panel-style furniture in the home, it gradually became the preferred manufacturing material of furniture factories, surface color and pattern are more. “Melamine”is one of the resin adhesives used to make such boards. Paper with different colors or textures is soaked in resin, dried to a certain degree, and then laid on particleboard or medium density fiberboard, or hard fibreboard surface, hot pressed into decorative board, specification name is melamine impregnated plastic film paper decoration, face artificial board, said its Melamine Board is actually said it is part of the finishing ingredients

Performance Characteristics Of MDF

The surface of density board is smooth and even, the material is fine and dense, the performance is stable, the edge is firm, and the adornment of the board surface is good. But the moisture resistance of density board is poor. And in contrast, the density of the nail grip than particleboard poor, screw tightening if loose, in the same position is difficult to be fixed. Folding main advantages 1, density board is easy to finish processing. All kinds of paint, paint can be evenly coated in the density of the board, is to do the paint effect of the preferred substrate. 2. Density Board is a kind of beautiful decorative board. 3. All kinds of wood veneer, printing paper, PVC, glue paper film, Melamine Impregnated Paper and light metal sheet can be used on the surface of density board. 4. The hard density board can be punched, drilled and made into sound absorption board, which can be used in the decoration engineering of buildings. 5, excellent physical properties, uniform material, there is no dehydration.

What Material Is Ambry Door Plank Used Good?

Solid Wood door board, use solid wood to make ambry door board, the style is more classic model, common price is taller. Its doorcase is solid wood, with cherry wood color, walnut color, oak color is given priority to. The solid wood door board divides the solid wood compound and the pure solid wood door board. Pure solid wood door board refers to the frame and door core board are solid wood. Solid Wood composite door board, core for the medium density board paste solid wood, generally in the production of solid wood surface to do concave-convex modeling, outside spray paint, so as to maintain the color and beautiful shape of the log. This can ensure that the special visual effects of solid wood, frame and core board combination can ensure that the strength of the door plate UV DOOR PANEL UV panel is the surface after UV curing UV paint treatment of the panel. UV is the abbreviation of Ultraviolet (UV) , UV paint that UV curing paint, also known as photo-triggered paint. Simply said is ordinary wood, silicon calcium plate and other plates through the UV paint, and then after UV curing machine drying and formed plates. Melamine Board the full name is melamine-impregnated plastic film coated artificial board, is a paper with different colors or textures into the melamine resin adhesive soaked, and then dried to a certain degree of curing, the utility model is paved on the surface of particleboard, medium density fibreboard or hard fibreboard, and is formed by hot pressing. Melamine decorative door plate, with a smooth surface, not easy to deformation, bright color, wear-resistant and corrosion-resistant advantages, and moderate price. With the original color seal note, give a unified visual effect.

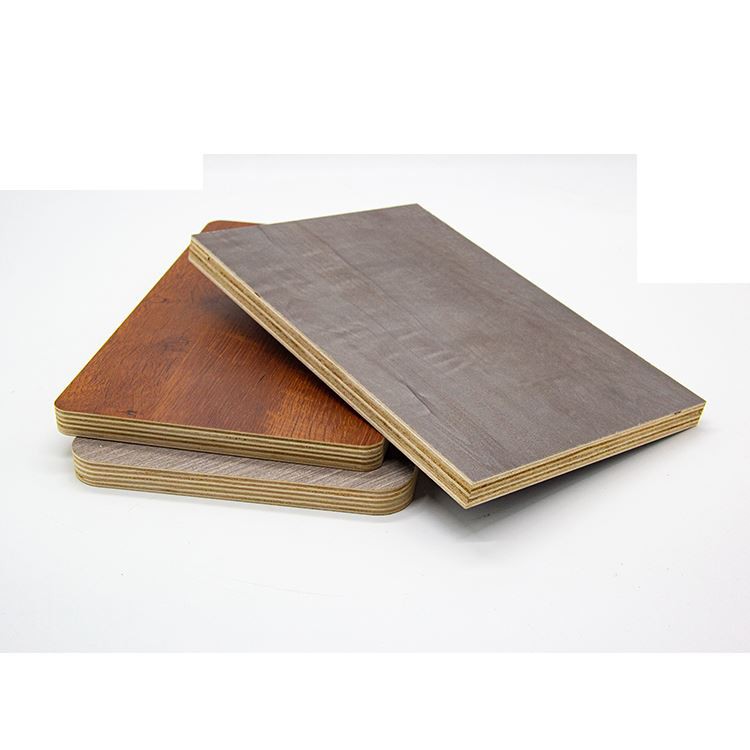

Multi-layer Solid Wood

Multi-layer solid wood to criss-cross multi-layer plywood as the base material, the surface of high-quality solid wood veneer or technology as a fabric, by cold-pressing, hot-pressing, sanding, health and other processes produced. As the multi-layer solid wood board is not easy to deformation and good indoor temperature and humidity regulation of the excellent performance, the surface layer of solid wood veneer material with natural texture and feel of real wood, so more selective. Therefore, by the consumer’s favor. Multi-layer solid wood board has good structural stability and is not easy to deform. Because of the vertical and horizontal gluing, high temperature and high pressure, the deformation defect of solid wood was solved from the aspect of internal stress. In the production process, the use of self-made high-quality environmental protection glue, so that the product formaldehyde emission limit to meet national standards, green environmental protection.

Spanish Plywood Giant Garnica Plywood Up For Sale

According to Spanish media reports, British venture capital fund ICG is currently gradually resuming the sale of Spanish plywood giant Garnica Plywood, with an initial valuation of about 500 million euros, which is expected to be favored by Spain’s large national private equity funds. It is reported that ICG acquired Garnica Plywood in 2016 for an unknown amount. At that time, ICG valued Garnica Plywood at about 250 million euros (plus equity and debt). Shortly after the acquisition, ICG had hired US commercial bank William Blair as financial advisor to coordinate the sale of Garnica Plywood last year. As a global leader in the poplar plywood industry, Garnica Plywood mainly produces industrial plywood, which accounts for more than 90% of its turnover.

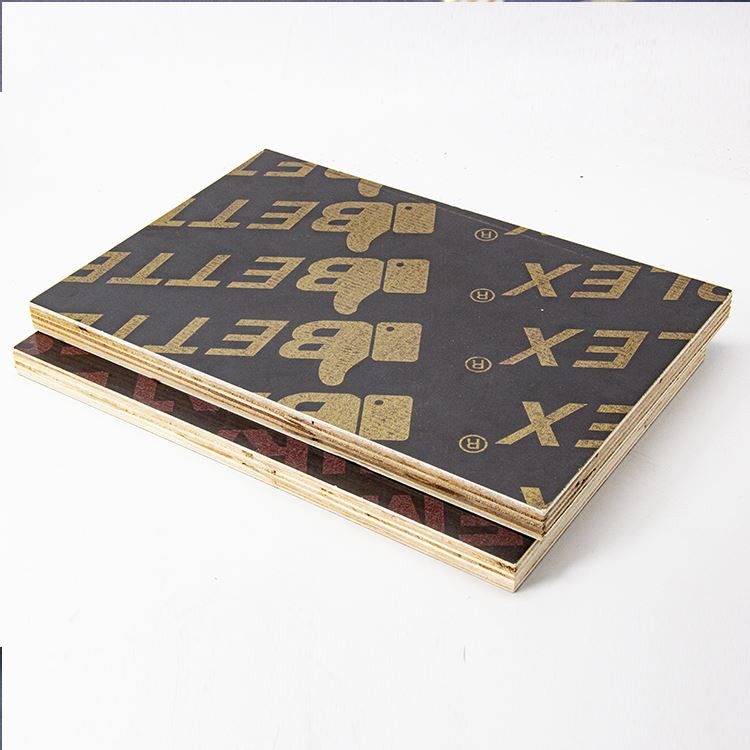

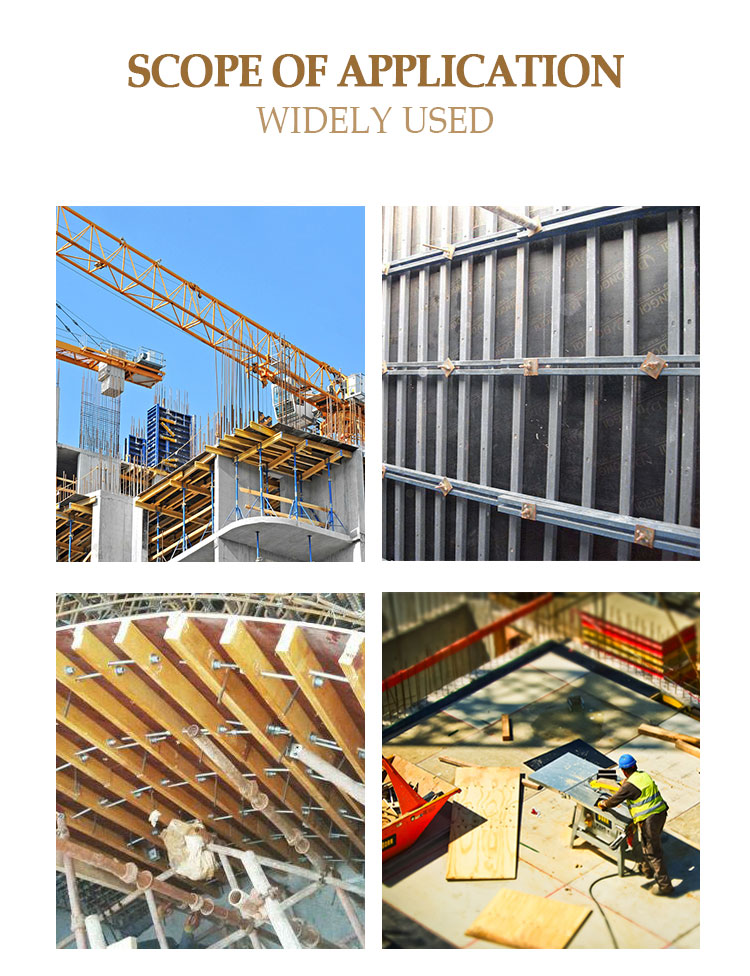

Film Faced Plywood

on surface we have black film, brown film, red film, and golden film. Film paper weight 120g/240g. These film paper totally waterproof You can put your company logo on the film, or use our company logo. -For the thickness, we can do 4mm to 25mm, size 1220x2440mm, 1250x2500mm, 610x2440mm or small size as you need. -For the core quality, we have join core, finger joint core, full core(full poplar core,combi core and full hardwood core) -For the film faced plywood reusing time, depending on different core quality and thickness. In general, we have three kinds of quality. They are joint core, finger-joint core and full core.

Film Faced Plywood Introduction Of Core Material

1)First is the joint core plywood sample. It is made from recycled material , cut into small strips. This is the cheapest one. From 12mm to 18mm can do joint core. You can see that the surface is not very smooth. The using times for joint core is about 1-5times(different thickness). But it can also carry weight. If you only use it for 1-2 times to build a lower building, and need cheapest price, joint core film faced plywood is the best choice for you. 2)Second one is finger-joint core.It is made from recycled plywood too. It cut finger like grooves out of the sides of the recycled plywood. This kind is stronger than the joint core but less strong than full core. The price of it is also between joint core and full core. It can be used for about 3-7 times(different thickness). If you want to have a better quality but limited budget, you can consider this one.this is most popular in Middle east/Souther east Asia/Africa market. 3)The last one is the full core film faced plywood sample. This kind is made from new fresh wood. We usually use full poplar core, and we also have hardwood core. It have the best quality. you could find that the layers are very regular and straight. And the surface is very smooth. We have one time hot press and two times hot press. For one time hot press full poplar core film faced plywood, it can be used for about 6-8 times. If you want to use it for about 10 times, you could try two times hot press one. It can be used for about 8-10 times and it has a better surface. Here is the sample. You can see the surface is very smooth and beautiful. It will give you a much smoother concrete surface.

New Products Supply To New Market

We supply mositure-proof MDF with 1220x2800mm size supply to South-America market with stable quality

Phenolic 18mm Film Faced Plywood For Shuttering Concrete Formwork

Dubai Wood Show 2023

Get ready for an immersive experience at the Dubai Wood Show 2023, taking place from 7 – 9 March 2023 at the Dubai World Trade Centre. Dubai WoodShow is one of the Largest and Most Anticipated Wood and Woodworking Machinery Exhibition in the Middle East and North Africa. Dubai Wood Show promises to showcase the latest advancements and innovations in the Wood and Woodworking Machinery Industry. With exhibitors from around the world, attendees will have the opportunity to Network, Learn and Discover new products and services. Don’t miss out on this opportunity to be a part of the Growing Wood and Woodworking Machinery Industry. Register Now and Be a Part of the Action! Exhibition Name: Dubai International Wood & Woodworking Machinery Show (DWS) 2020 Pavilion name and address Venue Name: Dubai World Trade Center (DWTC) Address of the exhibition hall: Dubai, United Arab Emirates PO Box 9292 We are participating in the exhibition, the booth is d-13c, the products we display are wpc wall panel, wpc decking, spc flooring, plywood, etc. Welcome to visit! Linyi Xhwood International Trade Co.,Ltd. Established in 2012,is a professional and responsible Supplier from Wood boards series to Decoration WPC Products and SPC products. Our New factory supply the WPC Series including Indoor WPC Wall Decoration Panel, Outdoor WPC Wall Panel, WPC Decking etc. WPC products are with long time service life ,around 20-30 years . The WPC material is composite of PVC and Wood, waterproof ,fire resistance,rot resistance and Eco friendly 0 emission! Our SPC Series including the PVC UV Marble sheet ,3D Marble Sheet, SPC Vinyl Floor and SPC Elevator Liners etc. Our company do the international export over 12 years, join in Alibaba over 9 year ,during this time ,our credibility always on the top ,never fail our clients for the quality and services,never! Welcome more friends come to inquiry and make the business ,we will not let you disappointed.