The Building Template Has An Important Influence On The Quality Control Of The Project In The Construction Of The Project

The building template has an important influence on the quality control of the project in the construction of the project. The smoothness and flatness of the formwork surface will directly affect the flatness of the engineering concrete surface. Therefore, template production should be based on strict production process control, and the production process technology should be improved in the links of raw materials, glue coating, hot pressing and trimming. The specific production process is as follows: 1. Raw material cutting: The raw material is cut according to the log. The log is cut horizontally according to a certain layer thickness, and the wood layer is cut into the same proportion according to the size of the template, and the wood layer is cut The magazine on the surface is removed, and the magazine can affect the adhesion fastness of the late glue. 2. Drying and drying treatment: The wood layer after cutting and peeling contains relatively large moisture. Therefore, for large-scale production, we need to dry it through a wood dryer, and the dried wood layer is relatively brittle Therefore, it should be placed naturally for 2-3 days to ensure the toughness of the wood layer. In a small amount of cases, we can use sunlight for drying. 3. Gluing and laminating treatment: A formed building template is made of multiple layers of wood panels and glued together. A special glue roller is installed to pass the wood panels through the glue filling machine. , The front and back sides of the board will be evenly coated with glue layer. Place the glue-coated wood board on the surface of the template, and evenly spread 6-10 layers (as required). 4. Hot pressing process: The template layer is laid by glue and flattened by hot pressing process. The traditional heating uses the boiler water to transfer heat for heating, and the modern equipment room uses electric heating. After flattening, the density of the building template can be increased, the forming is more regular, and the quality of the template is improved. The process of pre-pressing and then hot-pressing is adopted to reduce the probability of misalignment of the blanks to the highest degree, and then applying reasonable pressure and temperature to hot-press to ensure that each Chinese building template has good bonding strength and hardness. 5. Spray painting and trimming packaging treatment: After the heat-pressing treatment of the building template, there will be a few internal wood boards with misalignment and irregular corners. Use a knife to cut the excess boards, and spray anti-corrosion paint to prevent corrosion Paint is an important factor to ensure the service life and storage time of building templates. The construction template has the advantages of light weight, large bearing capacity, convenient use of bottled, smooth surface, and anti-corrosion.

Correct Selection Of Building Template

In the construction industry, every small difference may lead to the failure of the entire project. The construction template is also an important part. The correct selection of the construction template is as follows: 1. The construction of beam-column houses should adopt medium-sized composite building templates. Because of the large changes in the cross-section of beams and columns, it is not suitable to cut with multi-layer boards. 2. The wall formwork can be used as a medium-sized combined building formwork. As the general requirements of the same type of high-rise building group are uniform, the medium-sized combined building formwork helps to ensure a higher turnover rate. 3. The core tube of super high-rise or high-rise buildings should adopt “hydraulic climbing formwork”. The climbing formwork process combines the advantages of large formwork and sliding formwork. It can rise layer by layer with the construction of the structure, and the construction speed is faster, saving space and Tower crane hoisting times, safe high-altitude operations, no external scaffolding, construction, especially suitable for construction operations of steel structure concrete inner cylinder. 4. It is recommended to use the whole multi-layer board as the floor building template, and try to use the phenolic-clad 15-18mm thick multi-layer building template. The edge of this kind of building template is damaged after repeated use, so it must be cut in time to ensure that the edge of the multilayer board is flat.

Storage And Maintenance Of Building Templates

Building templates are widely used, and attention should be paid to maintenance and maintenance during daily use, so how to achieve correct storage and maintenance? 1. Pay attention to cutting. There are large and small building templates, which need to be cut according to different sizes and construction requirements. Construction templates of different shapes and sizes should be cut with a portable electric saw. After the cutting is completed, attention should be paid to the edge treatment to avoid causing damage to the building template. damage. 2. Protect the plane processing of the template. When using, pay attention to reducing metal corner scratches, bumps, falling on the surface, etc., and effectively protect the flatness, integrity, cleanness, and tidy of the formwork plane, especially in the concrete construction, the neat and level building formwork plane It can ensure the quality of concrete construction and improve the overall unity of the plane. 3. Reasonable storage. After the template is removed, use a scraper to clean the surface of the template better. After a long time of use, pay attention to oiling, stacking neatly, rejecting rain, sun and wind, and avoiding deformation and aging of the template due to changes in the external environment. The above is what we should pay attention to when building templates are used daily. Only by doing well in the details of use and storage can it prolong its service life and increase its turnover rate!

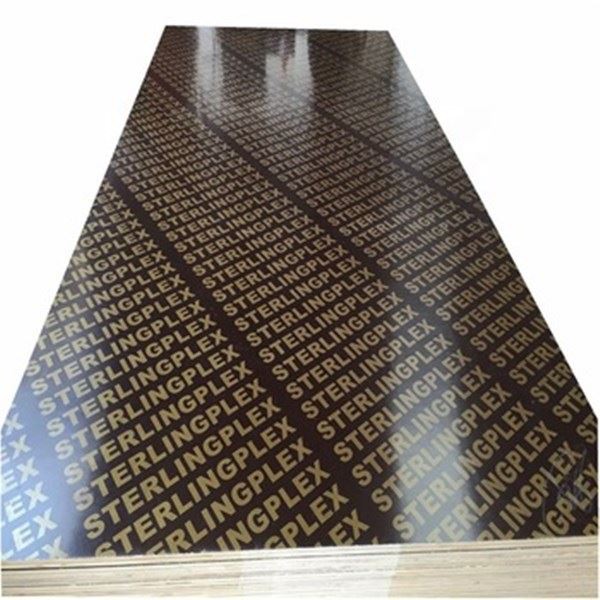

How To Identify The Quality Of Common Plywood Products

Nowadays, plywood is a three-layer or multi-layer plate-like material made of wood pieces that are peeled into veneers or sliced into thin wood, and then glued with adhesive. Generally, odd-numbered veneers are used and adjacent layers The fiber directions of the veneers are glued straight to each other. In order to improve the anisotropy of natural wood as much as possible, and make the plywood have uniform characteristics and stable shape, the structure of plywood generally must follow some principles and points, one is symmetrical, and the other is that the fibers of adjacent layers of veneer are straight. The principle of symmetry is to require the veneers at both ends of the center plane of symmetry of the plywood. Regardless of the nature of the wood, the thickness of the veneer, the number of layers, the fiber direction, and the moisture content, they should be symmetrical to each other. In the same plywood, a single tree species and thickness can be used. For boards, veneers of different tree species and thicknesses can also be used, but any two symmetrical veneer trees at both ends of the symmetrical center plane must have the same species and thickness. The front and back boards are not allowed to be the same tree species. Plywood manufacturers have learned that plywood is a common building decoration material in our lives, but there are many products on the market. If we want to use qualified products, we need to distinguish the quality of the products. To make the structure of plywood-plywood conform to the above two basic principles, its number of layers should be odd, so plywood is generally made of three, five, seven and other odd layers. The surface veneer is called the surface board, the inner veneer is called the core board, the front surface board is called the front board, and the back surface board is called the back board. In the core board, the fiber direction parallel to the surface board is called the long core board or In the middle plate, when forming the cavity table slab, the front plate and the back plate must face outwards tightly.

What Are The Common Formwork Engineering Construction Problems

Building formwork is the most widely used formwork on construction sites. During the construction of this formwork, I still encounter some accidents, so safety must be considered when constructing building formwork. 1, accident In the process of installing the building formwork, if the formwork is configured, it is easy to get electric shock and mechanical damage. Not only that, it is very easy to be injured by objects falling from a high altitude during the installation and removal of the formwork. In addition, in the concrete During the construction of pouring, the formwork may collapse. 2, security issues First of all, during the installation of the building template, it is necessary to ensure that the bottom of the template must be firmly nailed with the template to avoid accidents of collapse. During the construction process, you must not work on the building template or steel reinforcement.

The Future Development Of Building Formwork

The advantages of building formwork are smooth and smooth surface, easy to demould; strong abrasion resistance; good waterproofness; formwork strength and rigidity, long service life; light material, suitable for processing large area use, and has broad development prospects. Its main manifestations are as follows: 1. The prospect of WPC products for building formwork is broad. Wood fiber embedded in a material that has high decay resistance and can absorb moisture. With good processing performance and the use of traditional woodworking tools, sustainable materials can be formed. 2. Has good product mechanical properties. The polymer with the most orderly mechanical properties of WPC products has lower strength and stiffness than wood, reduces moisture absorption and freeze-thaw cycles, and has strong variability. With the increasing number of building constructions, its ever-changing building templates present new materials and new technologies to meet different needs, and have won a bright future for promoting the development of building templates!

What To Pay Attention To When Processing Plywood In Spring

The new crown epidemic has slowly been brought under control, various industries have begun to resume work, and sheet metal manufacturers have begun to return to production. However, plywood manufacturers still need to pay attention to the processing of panels in the spring. Although spring is warmer than winter and drier than summer, it is also windy and sandy and the climate is drier. Any carelessness in these climate characteristics will have an adverse effect on sheet metal processing. When plywood manufacturers process boards in spring, they must first pay attention to avoiding windy weather, because the dust on the ground is blown by the wind, the surface of the plywood and the glue layer will be contaminated with dust, resulting in weak bonding or messy board surface, which is not conducive to board sales. When processing plywood in spring, manufacturers should also pay attention to fires that may be caused by dry climates. After all, the boards are flammable. The warehouses where plywood manufacturers process boards are required to be dry and free of open flames. Workers are prohibited from smoking in the workshops and sufficient fire-fighting equipment is prepared to be prepared for the fire. In addition, although the spring rain is not heavy, the impact of continuous spring rain is not small. Therefore, the manufacturer should transfer the panels placed in the open air to the room before the spring rain, and try not to process the panels on rainy days, so as to prevent the panels from getting damp and reducing the bonding ability.

There Is A Lot Of Rain This Summer, Plywood Manufacturers Should Pay Attention To Storage

What is your impression of summer? Strong sunlight and lingering heat? This summer is different. The north is generally rainy, and the sultry weather hits from time to time. How do plywood manufacturers store their boards in such weather? Generally speaking, whether it is hot and sunny weather or sultry rainy weather, it is not conducive to the storage of plywood. Plywood exposed to the sun for a long time may crack and degummed, and the rain-drenched plywood may become moldy. Especially in this summer, there is a lot of rain. Plywood manufacturers must take moisture-proof measures when storing. The boards that have passed the quality inspection should be packaged and transported to the warehouse in time to reduce the time of staying outdoors to avoid sudden heavy rains that may cause the boards to get damp. The warehouse for storing plywood requires dry ventilation, so that even if it encounters heavy rain, the window can be opened as soon as possible after the rain to dissipate the moisture and prevent the board in the warehouse from getting damp. Plywood manufacturers should place the boards away from doors and windows to avoid moisture. There is a lot of rain this summer. Manufacturers should produce plates on demand. Do not stock up too many plates in the warehouse to avoid slow sales.

Plywood Should Not Be Exposed To The Sun For A Long Time

Summer is coming when the temperature is quite high. For manufacturers engaged in sheet metal production, such weather is suitable for producing all kinds of sheets. However, plywood manufacturers also need to pay attention that the finished plywood should not be exposed to the sun for a long time. The board is glued according to the standard, and the result is plywood. Although plywood is not as collectible as solid wood, it has a low production cost and is strong and durable. It is a good choice for making ordinary furniture and cabinets. Plywood manufacturers can provide consumers with various types of panels, such as ecological panels, special-grade panels, five-ply panels, etc. The types and specifications are very good, and the quality is also very good. The high temperature in summer is beneficial to the drying of the boards, and it is also the peak period of plywood production. However, the panels completed by plywood manufacturers cannot be exposed to the sun for a long time, which will easily lead to excessive drying and cracking of the panels, and it will also easily cause the glued panels to separate, which will affect the use effect and shorten the service life. To store plywood in summer, choose a dry and dark place, away from water and open flames, and be safe and secure

Can Plywood Be Stored In The Open Air

Plywood is a kind of board that is often used to make furniture, cabinets, etc. Although it is not as beautiful as solid wood and has collection value, it is really popular because of its lower cost. Plywood manufacturers produce panels in large quantities every day and store these panels in the open air. Regardless of whether it is a board or other products, as long as it is made of wood, it is easy to be affected by moisture, cracks, etc., which affect the appearance and use. Although plywood manufacturers know this truth well, because of the limited storage space and the need to dry new boards to remove water, they still have to be stored in the open air for a period of time. During this period of time, manufacturers should pay close attention to changes in weather, cover the plates with plastic sheets in time on cloudy and rainy days, or transport the plates indoors to prevent the plates from being damp and degumming. Although the summer temperature is high, it can speed up the evaporation of water from the board, but the plywood exposed to the sun for a long time is also prone to degumming. Therefore, the plywood manufacturers should pay attention to the influence of temperature when storing the boards in the open air. When the sun is too strong, try to reduce the time of plywood storage in the open environment.